Based on the advancements in science and technology, most human power sources continue to rely on heat engines. These encompass fuel-based heat engines, which involve the direct combustion of fuel, alongside various intermediate heat engines (also known as external combustion engines). These intermediate engines function by converting temperature and pressure within heat-absorbing and heat-releasing mediums.

So, when it comes to nuclear-powered aircraft carriers, the nuclear reactor we hear about is just the heat source of a dielectric heat engine.

Its essence is actually not much different from the train that has been used for more than 200 years.

The train generates heat by burning coal, which heats the water in the overheating pipe (30) in the train boiler to evaporate and boil to form water vapor. High temperature and high-pressure water vapor enter the air chamber of the locomotive (26). Then, the high-temperature and high-pressure steam enters the Vals-Shielz valve, driven by the wheel mechanism; the steam makes the piston reciprocate.

In this process, water is heated into water vapor to complete the coal fire’s thermal energy conversion into kinetic energy.

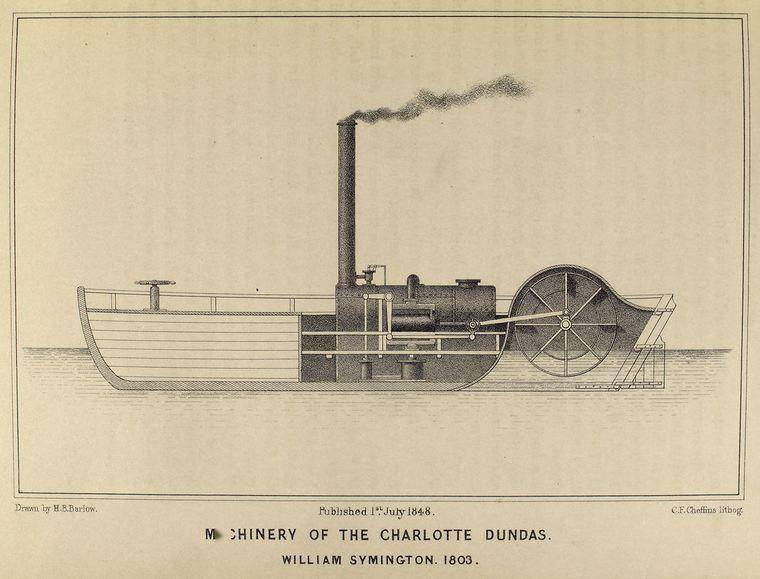

Early steamships were actually the same as steam trains, except that the steam engine did not drive wheels but webbed wheels to move the water.

At this time, the steam output power still relies on the reciprocating motion of the cylinder.

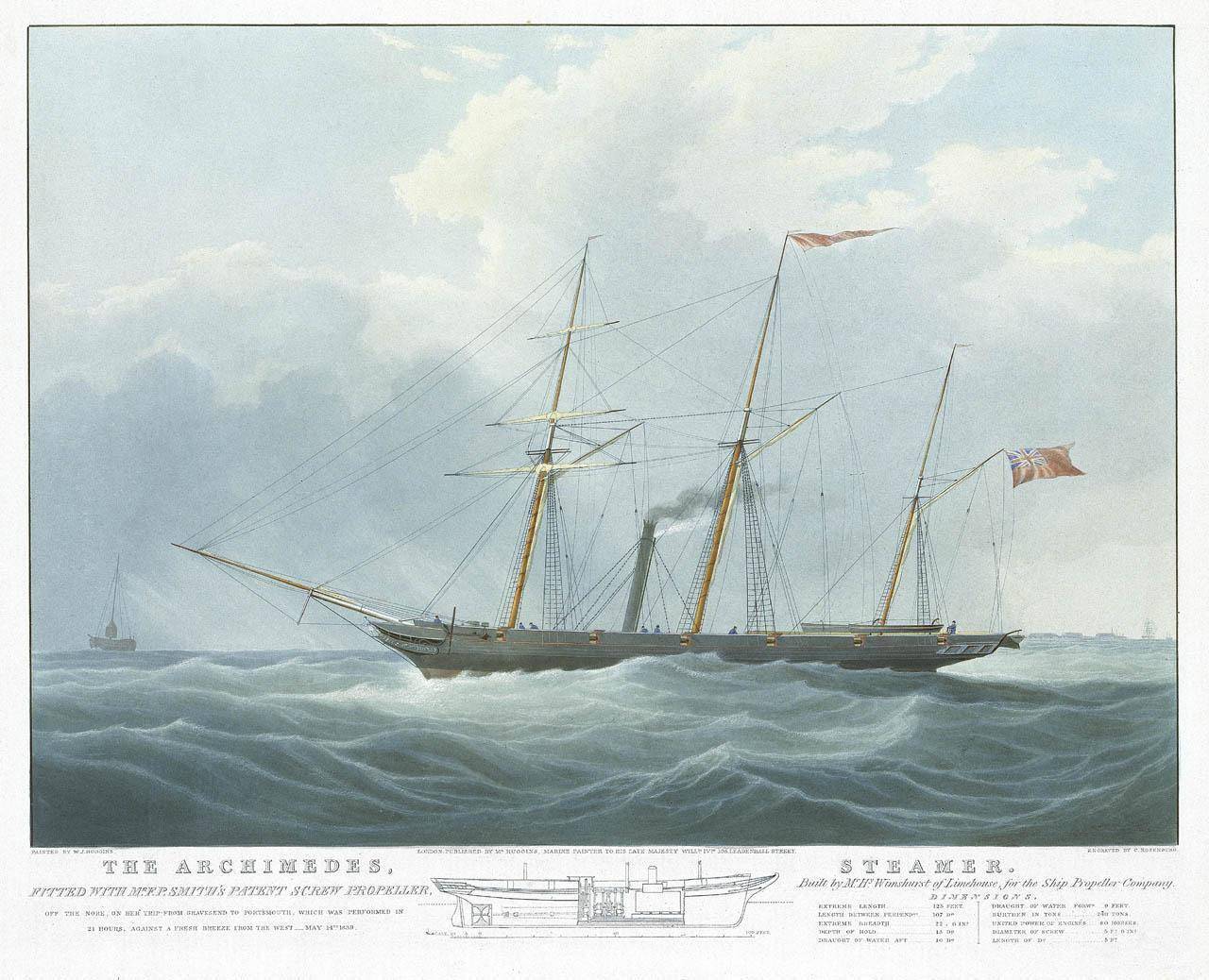

When power was implemented in ships, an ancient design was used in ships. This design originated from Archimedes and was first used by the ancient Greeks to lift water for irrigation.

This is the Archimedes screw pump.

This mechanical device uses a screw rod to lift water to a high place. On October 18, 1838, the steam schooner Archimedes was launched.

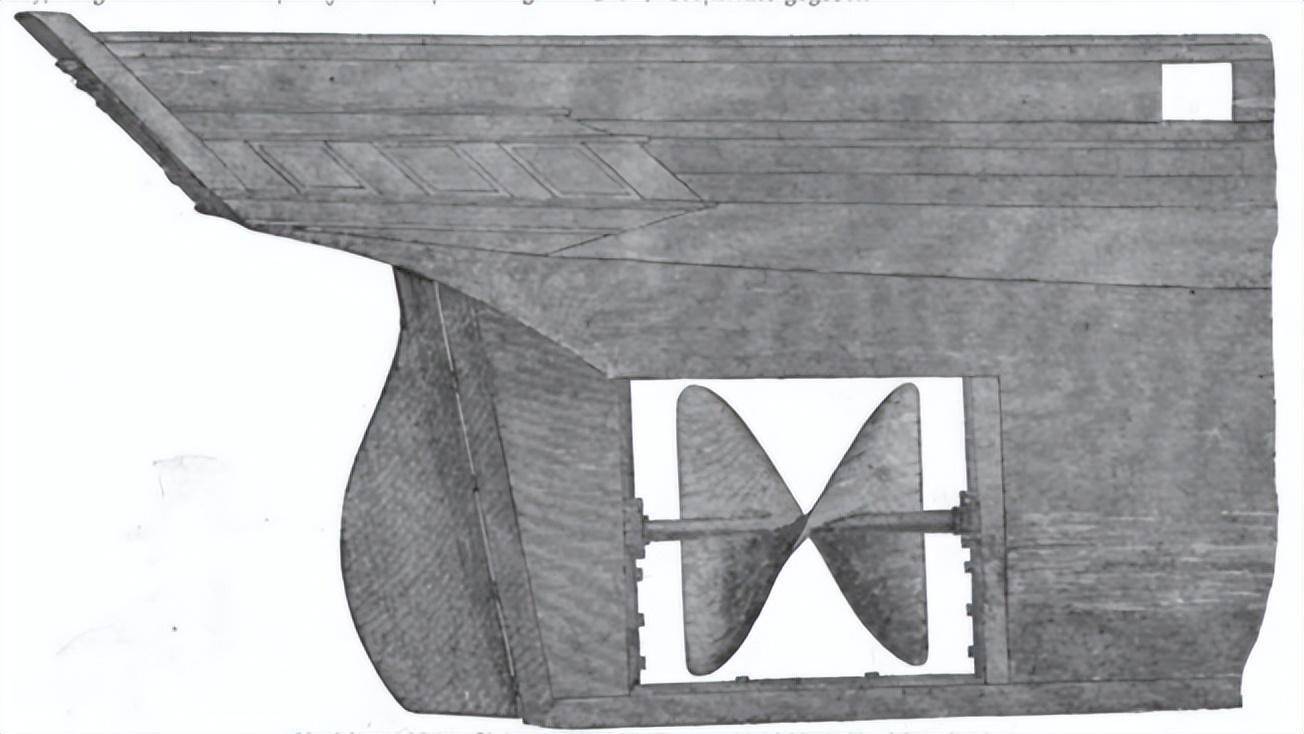

It was the first ship propelled by a propeller.

Its propeller is exactly an Archimedes spiral.

When “high-speed rotation” can be used as the propulsion form of ships, the power design of large ships becomes the subject of “how to make the heat engine rotate directly”.

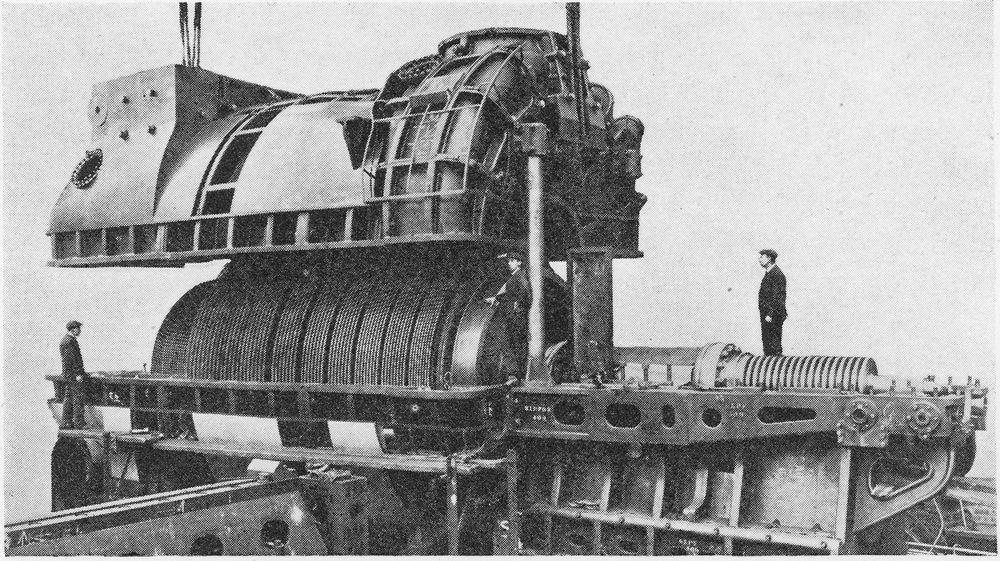

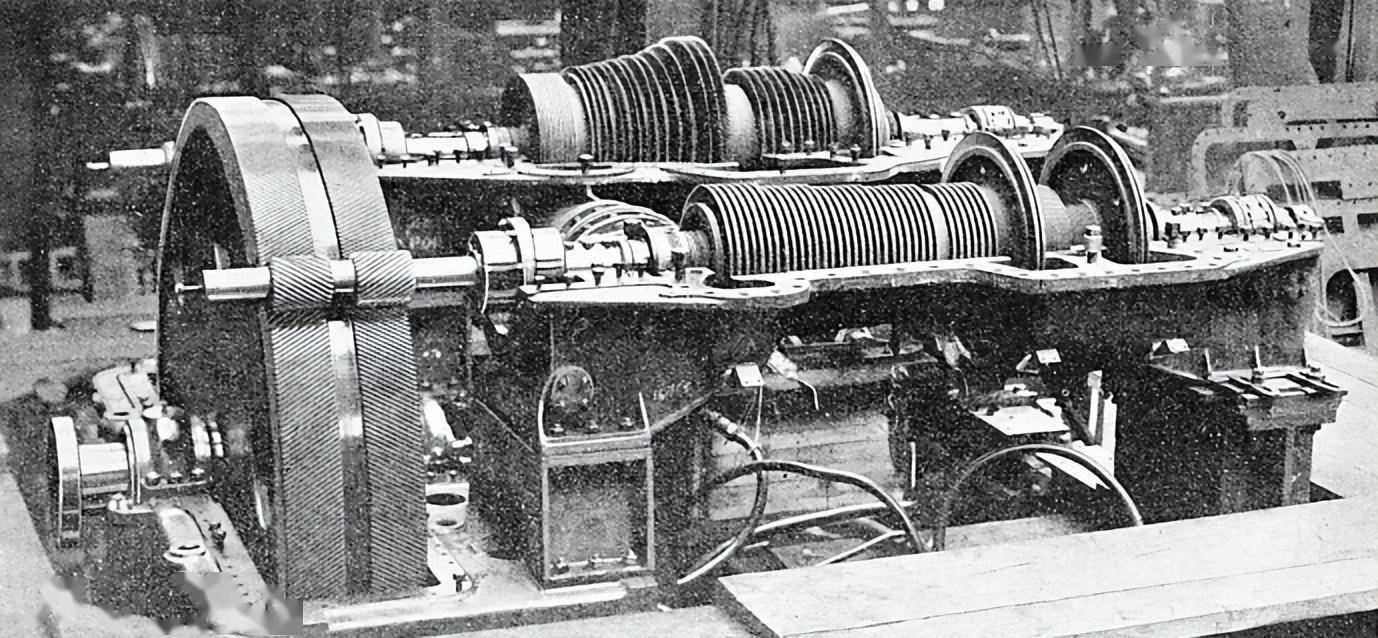

In World War II, large warships generally adopted steam turbines as the conversion mechanism of steam internal energy to kinetic energy.

This thing is actually very simple. When the high-temperature and high-pressure steam enters the steam turbine, it will drive the turbine of the steam turbine to rotate, and then the steam turbine will output power through the main shaft.

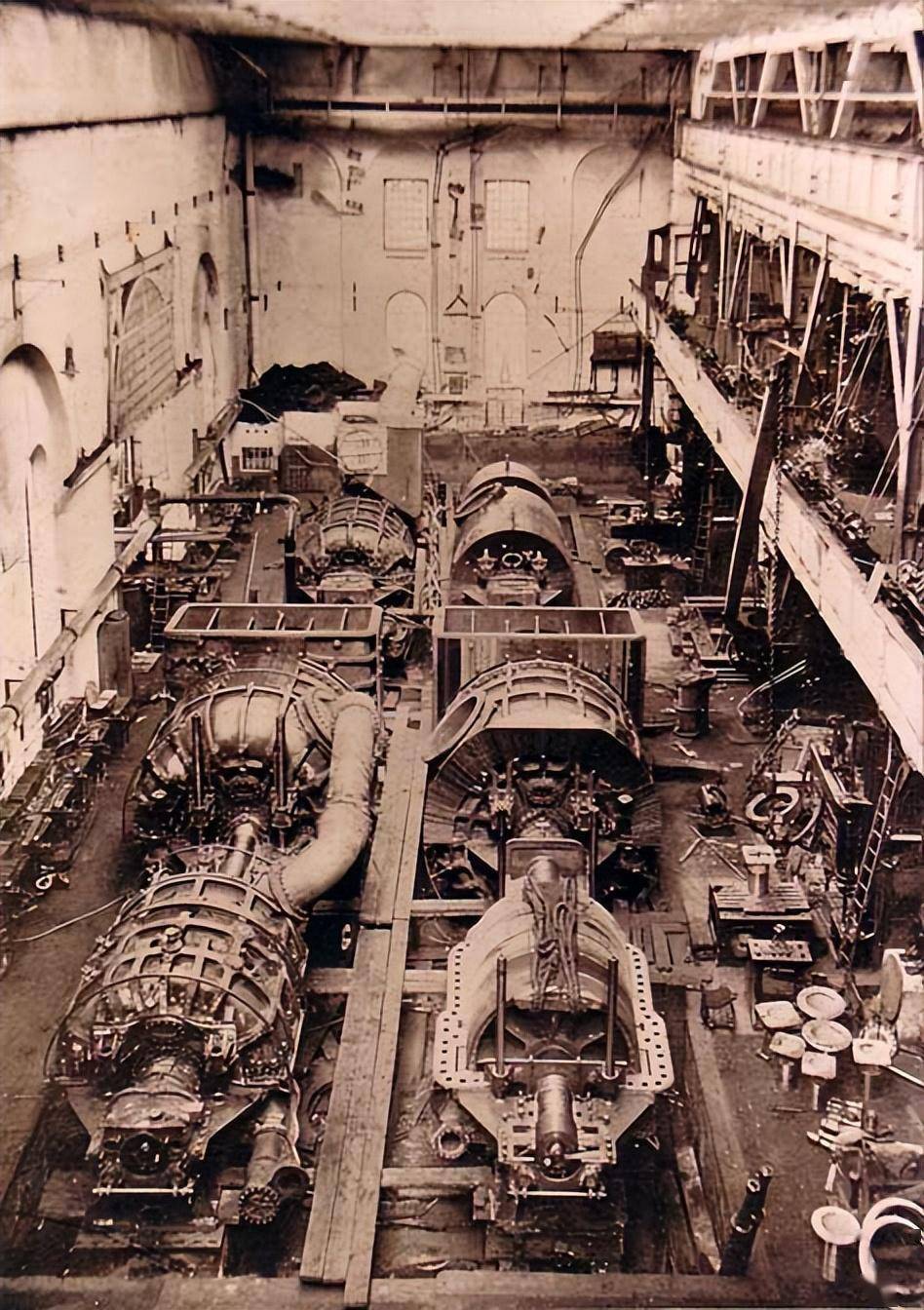

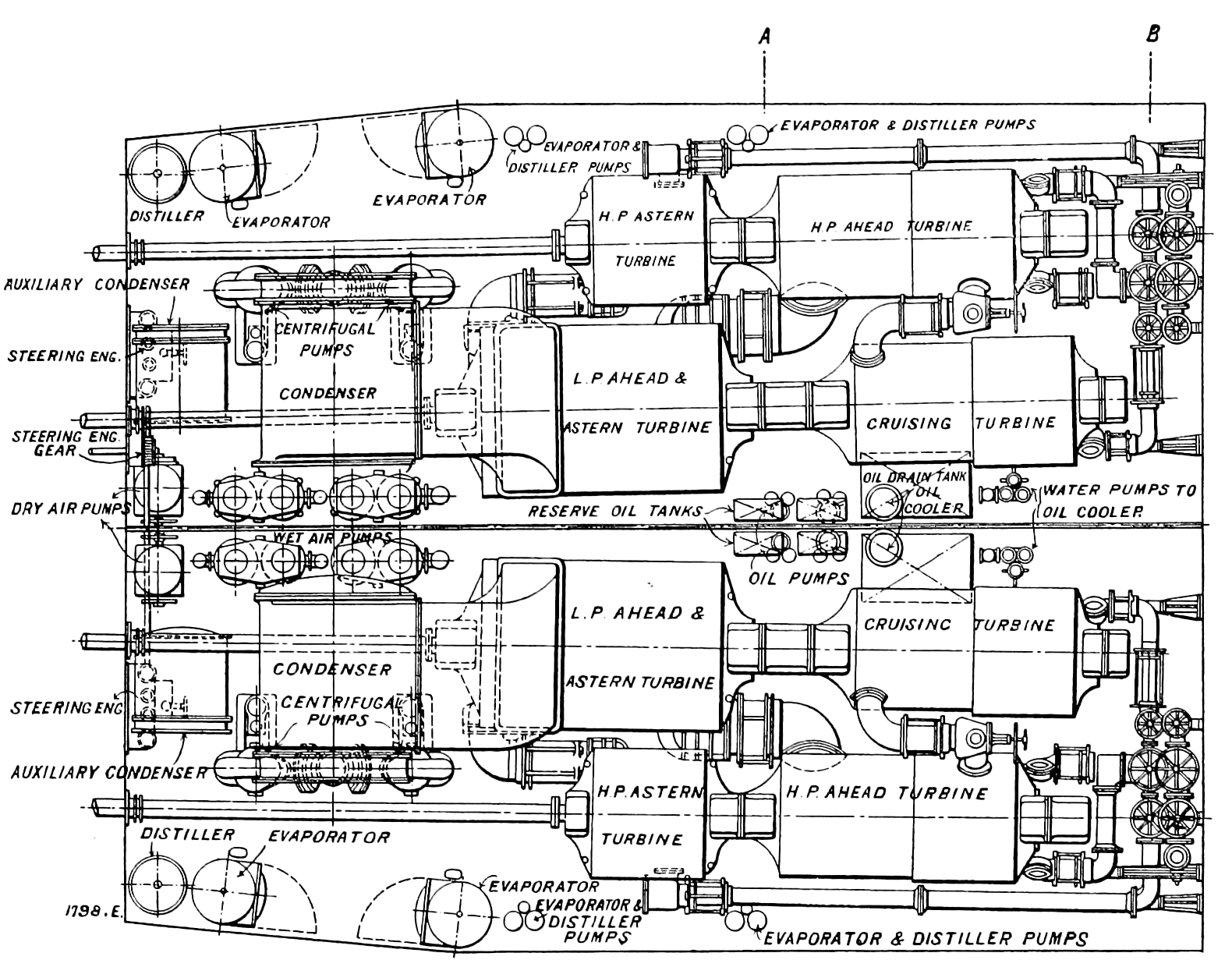

When the energy output by one steam turbine is not enough, multiple steam turbines can even be used in parallel to obtain greater power output.

The main shaft of most steam turbines is directly connected to the propeller through the shaft. There is no series of energy conversion processes such as electric energy and gearboxes at all.

In the engineering drawing of the battleship above, we can find four turbines and a long protruding main shaft. This is currently the most efficient form of power output for steam turbines. To adjust the speed, you only need to adjust the steam flow to the steam turbine without too many mechanical speed adjustments.

As for how much speed needs to be adjusted, it’s really not like a car in gear. A device called a “car clock” is used in large ships.

This command transmission device sounds when a new gear is set, hence the name “bell”. One is installed on the bridge, and the corresponding other one is installed in the engine room. When the clock on the bridge is turned, the clock in the engine room will sound, and the internal pointer will point to the corresponding gear.

After the people in the engine room set the steam flow rate and boiler temperature according to the rules, they went to pull the car clock in the engine room, and the car clock on the bridge also responded. This is a fairly rapid command delivery system. But the instructions are communicated not to the machine but to the people on either side of the clock.

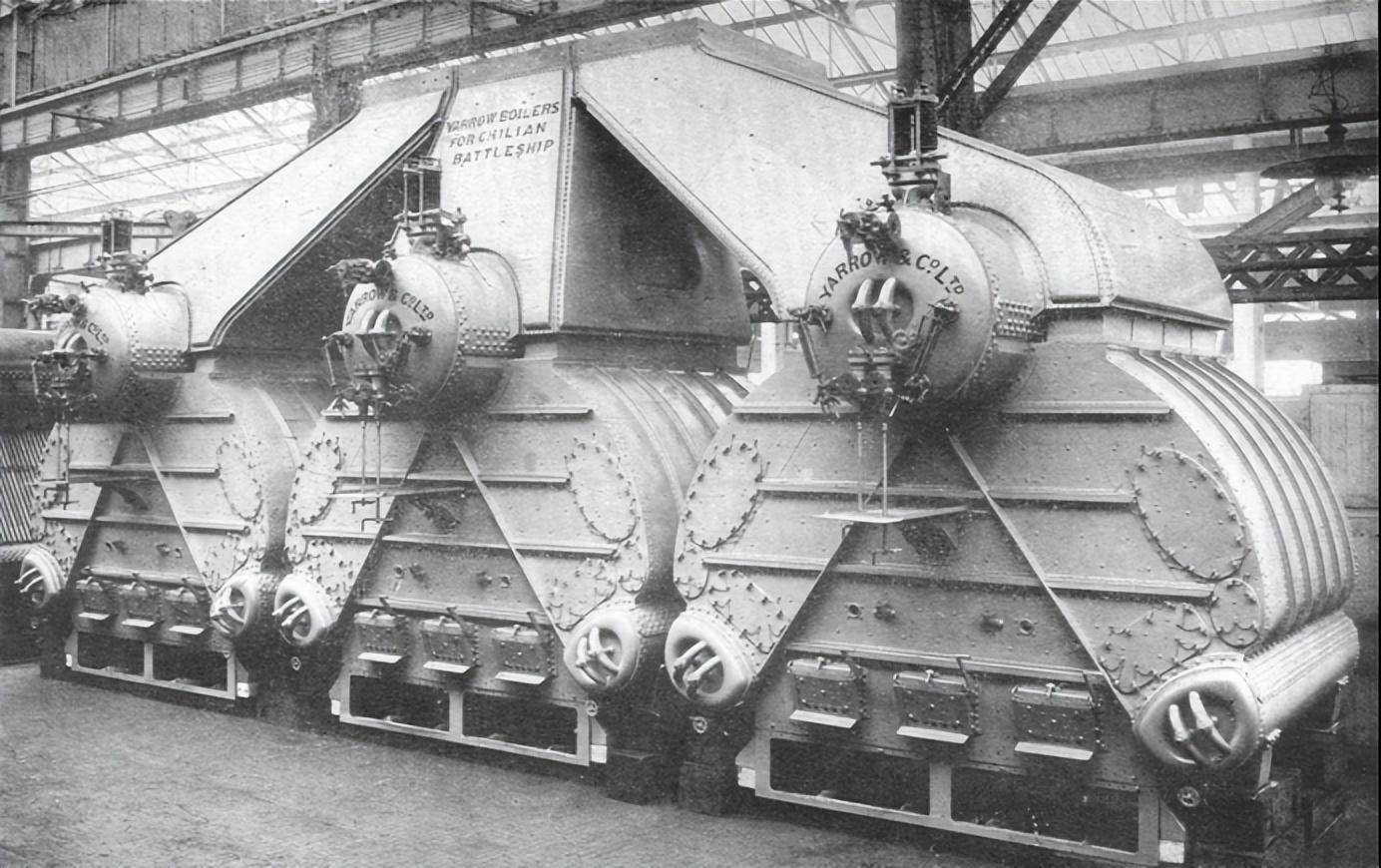

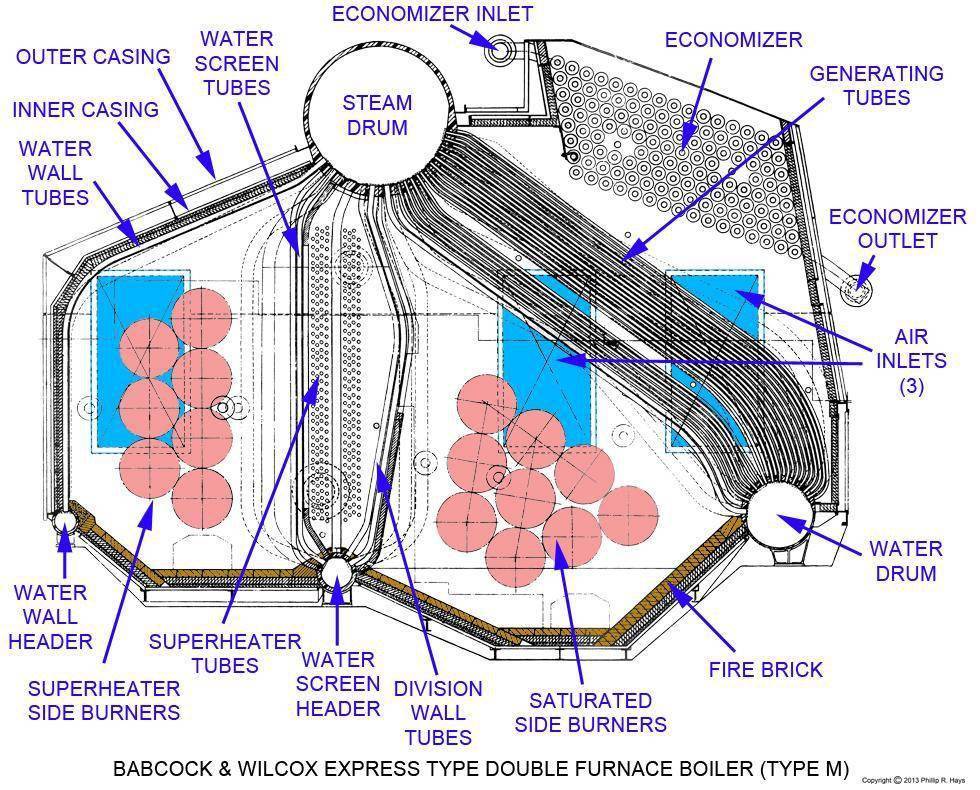

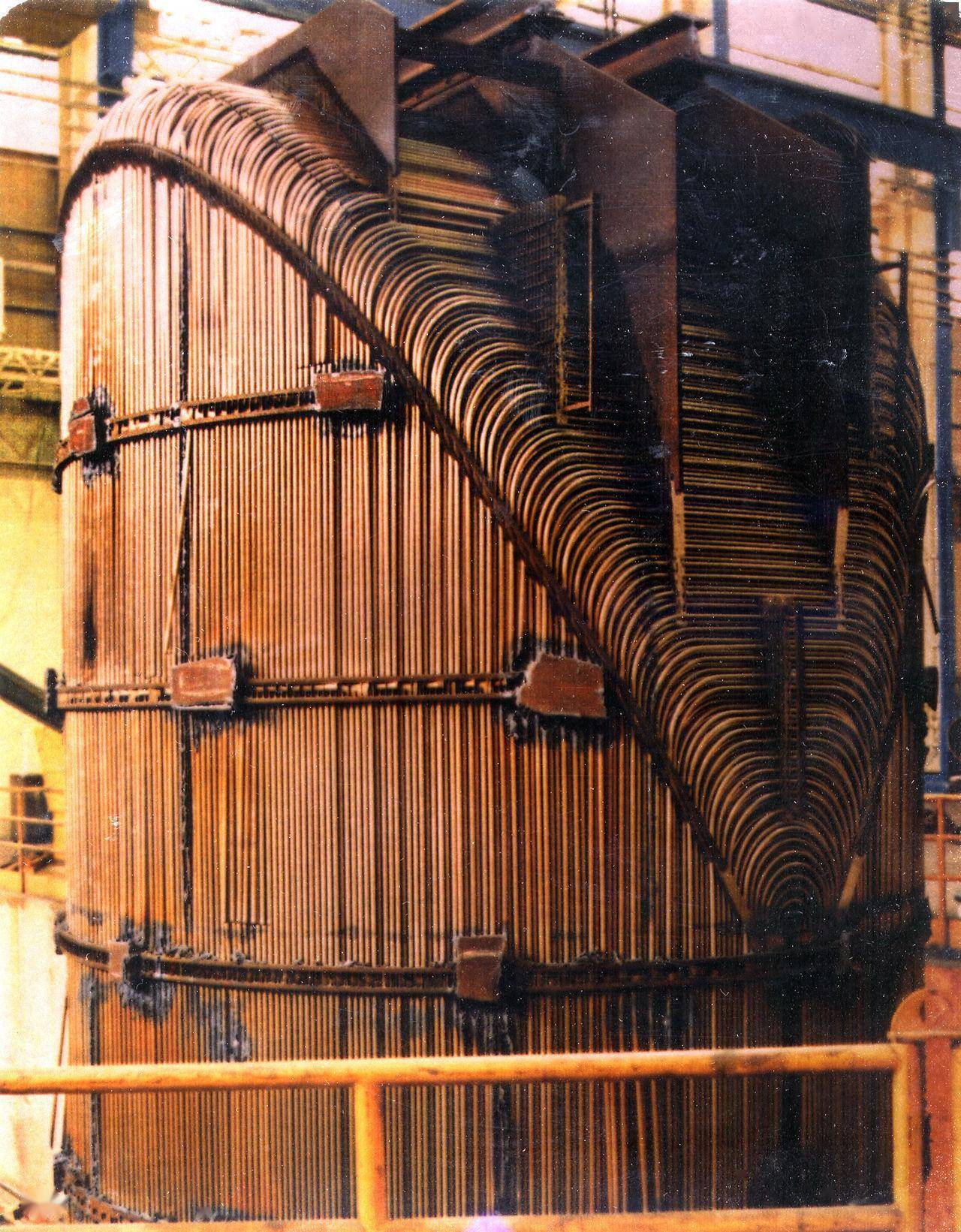

The steam turbine solves the power output part of the ship, and the source of steam depends on the boiler.

The structure of a typical marine boiler is similar to the structure of the steam train we talked about at the beginning. They are both a lot of water pipes burning in the fire.

The high temperature of the fuel heats the moisture in the water pipes to generate steam, which is sent to the steam turbine to drive the turbine to rotate.

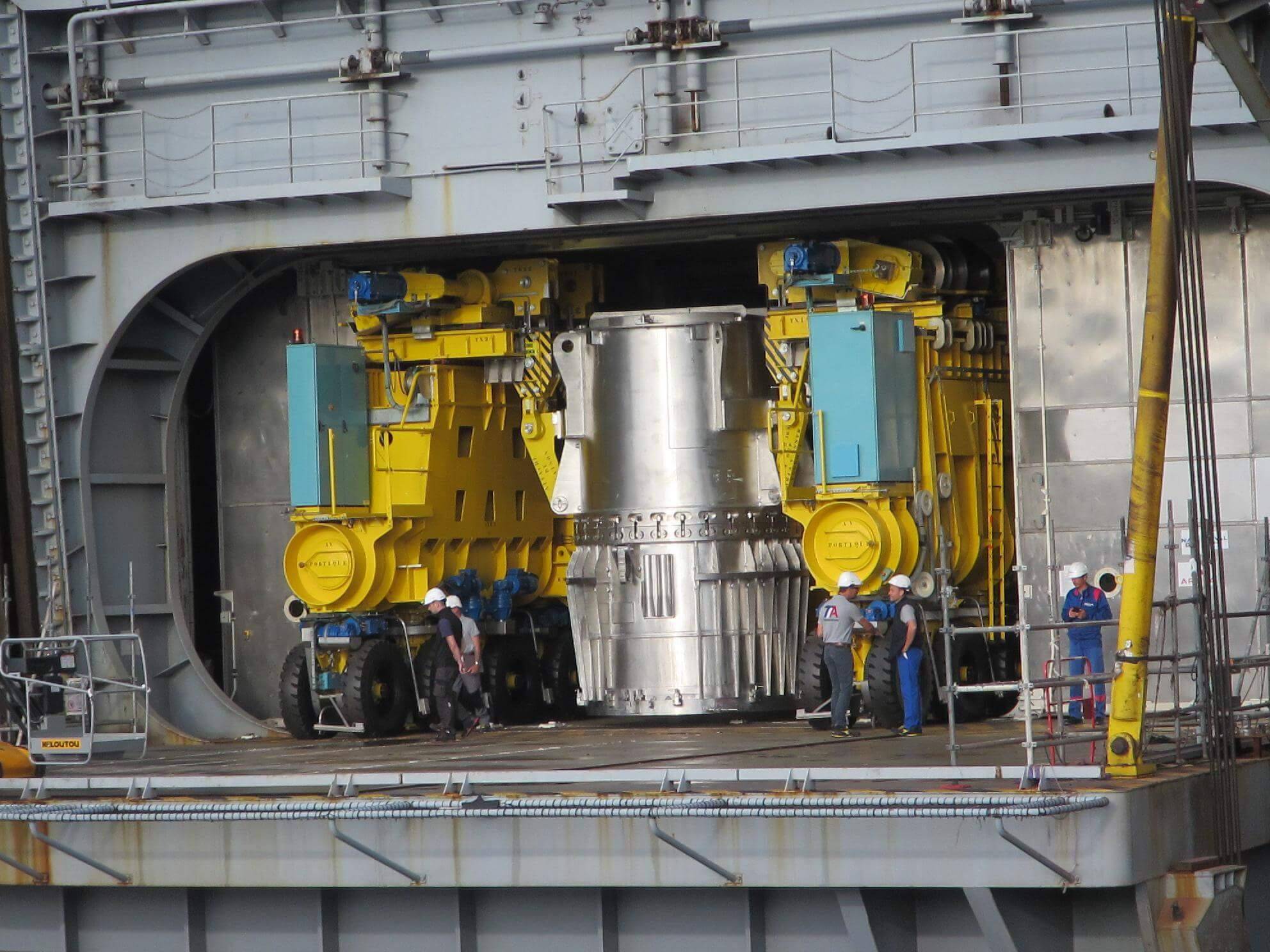

Of course, there is another option for modern large ships, which is “nuclear power”, which uses the heat from nuclear reactors instead of boilers to produce water vapor.

France’s Charles de Gaulle is replacing its nuclear reactor

In the entire power system of a nuclear-powered ship, the role of the nuclear reactor is only equivalent to the fuel in the boiler, and the core temperature of the nuclear reactor will be maintained at about 900˚C. Since nuclear power reactors are closed, we need to derive the core’s temperature. At this time, the circulatory system needs to be used.

The idea is the same as that of a water-cooled computer, which still uses water to dissipate heat. It’s just that the water in the nuclear reactor is maintained at 150 atmospheres. Under this pressure, the water can be kept below 340 degrees without boiling. The massive flow of water removes the heat generated by the reactor core.

While absorbing heat from the reactor, the ultra-high-temperature water is introduced into the heat transfer tube of the secondary evaporator.

The pressure in the secondary evaporator is 70 standard atmospheres, and the water will start to boil at about 260 degrees, producing high-temperature and high-pressure steam.

There is steam now. The steam can be introduced into the turbine through the pipeline to drive the turbine to rotate.

The steam that drives the turbine enters a cooling unit where it cools down into water, then flows into the steam generator again, and the cycle repeats.

Seeing this, you will understand that a nuclear reaction is actually a boiler. How we drive aircraft carriers to sail is not much different from 200 years ago, and we still boil water.